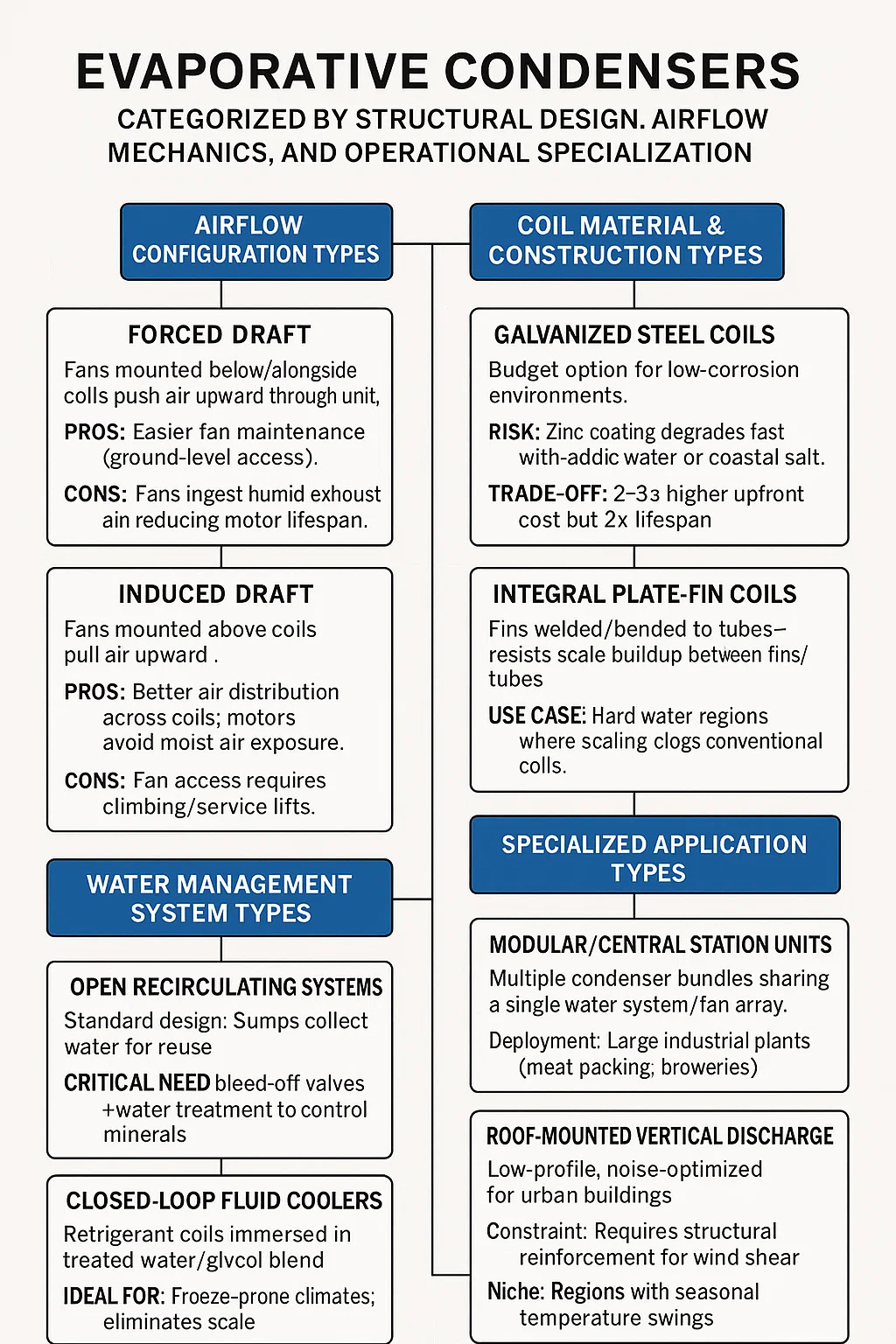

Evaporative condensers are categorized by structural design, airflow mechanics, and operational specialization. Below is a field-focused breakdown of common types:

Content

1. Airflow Configuration Types

•Forced Draft

Fans mounted below/alongside coils push air upward through the unit.

Pros: Easier fan maintenance (ground-level access).

Cons: Fans ingest humid exhaust air, reducing motor lifespan.

•Induced Draft

Fans mounted above coils pull air upward.

Pros: Better air distribution across coils; motors avoid moist air exposure.

Cons: Fan access requires climbing/service lifts.

2. Coil Material & Construction Types

•Galvanized Steel Coils

Budget option for low-corrosion environments.

Risk: Zinc coating degrades fast with acidic water or coastal salt.

•Stainless Steel Coils

For harsh environments (chemical plants, coastal sites).

Trade-off: 2–3× higher upfront cost but 2× lifespan.

•Integral Plate-Fin Coils

Fins welded/bonded to tubes – resists scale buildup between fins/tubes.

Use Case: Hard water regions where scaling clogs conventional coils.

3. Water Management System Types

•Open Recirculating Systems

Standard design: Sumps collect water for reuse.

Critical Need: Bleed-off valves + water treatment to control minerals.

•Closed-Loop Fluid Coolers

Refrigerant coils immersed in treated water/glycol blend.

Ideal For: Freeze-prone climates; eliminates scale but reduces efficiency.

4. Specialized Application Types

•Modular/Central Station Units

Multiple condenser bundles sharing a single water system/fan array.

Deployment: Large industrial plants (meat packing, breweries).

•Roof-Mounted Vertical Discharge

Low-profile, noise-optimized for urban buildings.

Constraint: Requires structural reinforcement for wind shear.

•Hybrid Dry/Wet Units

Operates as air-cooled condenser until ambient exceeds threshold, then switches to evaporative mode.

Niche: Regions with seasonal temperature swings.

English

English عربى

عربى