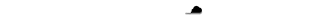

An evaporative condenser integrates air cooling and water evaporation to reject heat from refrigeration systems. Its design and operation differ fundamentally from standard air-cooled condensers:

1. Core Working Principle

Combined heat transfer:

Refrigerant heat dissipates through both:

Sensible heat transfer (air cooling coils)

Latent heat absorption (water evaporation)

Water spray system:

Pump circulates water over condenser coils.

Evaporating water absorbs significant heat, lowering refrigerant condensing temperature.

2. Critical Components

Condenser coil bundle:

Tubing circuit where hot refrigerant flows.

Typically copper or stainless steel for Typically copper or stainless steel for corrosion resistance.

Water distribution system:

Spray nozzles coat coils evenly; clogged nozzles cause dry spots and inefficiency.

Fans and airflow:

Forced-draft (fans atop unit) or induced-draft (fans below) configurations.

Air pulls through saturated coils, accelerating evaporation.

Sump and water treatment:

Collects and recirculates water.

Bleed-off valve controls mineral concentration.

3. Key Advantages

Superior efficiency in high ambient temps:

Water evaporation enables condensing temperatures below dry-bulb air temperature.

Reduced compressor workload:

Lower head pressure cuts energy use 20–30% vs. air-cooled units in arid climates.

Compact footprint:

Handles equivalent heat rejection with smaller coil surface vs. dry smaller coil surface vs. dry condensers.

4. Operational Constraints

Water quality demands:

Hard water causes mineral scaling; requires softeners/chemical treatment.

Poor treatment risks Legionella growth.

Freeze protection:

Winter operation demands glycol additives or drain-down in cold climates.

Drift and water loss:

Wind carries water droplets ("drift") – requires eliminator baffles.

Evaporation consumes water; unsustainable in drought regions.

5. Ideal Applications

Industrial refrigeration (cold storage, food processing).

High-ambient environments (desert climates).

Sites with abundant water but limited electrical capacity.

Maintenance Imperatives:

Scale removal: Acid washing coils annually. removal: Acid washing coils annually.

Drift eliminator cleaning: Prevents airflow blockage.

Bioprotocols: Quarterly Legionella testing for water systems.

English

English عربى

عربى