The condensing unit has critical applications in the medical cold chain, mainly ensuring the safety of drugs, vaccines, and biological products through precise temperature control. The following is a breakdown of specific application scenarios:

1. Drug storage

Constant temperature refrigeration equipment used in hospital pharmacies and pharmaceutical warehouses to ensure the stability of temperature sensitive drugs such as antibiotics and insulin. The condensing unit maintains a low temperature environment of 2-8 ° C through continuous refrigeration to prevent drug failure or deterioration.

2. Vaccine cold chain

In the transportation and storage of vaccines, the condensing unit provides precise temperature control (such as -15 ° C to -25 ° C) to ensure vaccine activity. For example, medical refrigerators using air-cooled units can maintain a constant temperature during power outages or long-distance transportation, reducing vaccine loss.

3. Preservation of biological samples

The biological samples such as plasma and cell tissue in the laboratory need to be stored in an ultra-low temperature environment (such as below -30 ° C) for a long time. The condensing unit is combined with an efficient compressor to achieve rapid cooling and stable temperature control, preventing sample degradation.

4. Aviation cold chain transportation

For cross-border medical transportation (such as emergency drugs), aviation temperature control boxes equipped with DC condensing units can continuously cool during flight. By pre freezing eutectic plates, low temperatures can be maintained for several days without the need for an external power source, meeting international transportation safety standards.

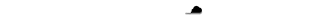

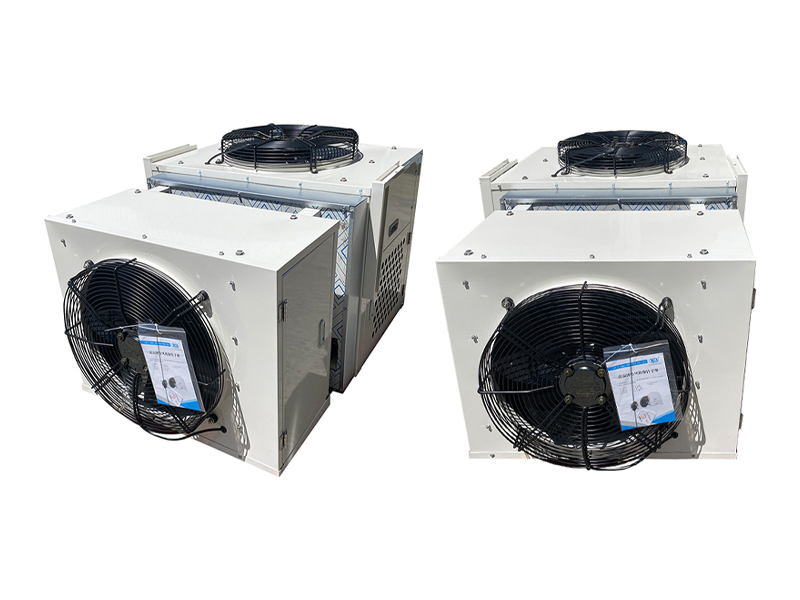

The core advantages of medical condensing units are strong adaptability (such as air-cooled design without external water cooling), low failure rate to ensure continuous operation, and precise temperature control to avoid waste of medical resources.

English

English عربى

عربى